- Telefon: 0 (232) 486 05 86

- info@kossecomposite.com

A composite material can be defined as a combination of a matrix and a reinforcement, which when combined gives properties superior to the properties of the individual components.

Fiberglass is a polymer made from a plastic matrix that is reinforced by fibers of glass. It is a popular material because it is inexpensive to make, and its strength and weight properties compare favorably against those of metals for many applications. Fiberglass has a wide range of applications and is commonly used in glider aircraft, boats, cars, showers and bathtubs, roofs, pipes, and surfboards.

Glass reinforced plastic is lightweight and has good thermal insulation properties. It has a high strength to weight ratio, making it useful for the production of products such as water tanks, surfboards, canoes, small boat hulls and similar products.

A mould in the shape of the final component is required. The reinforcement (as a woven fabric)is carefully laid into this mould and the matrix (resin) is poured on and spread, usually with the aid of a roller. This is then left to cure. A gelcoat can be added to the mould before the reinforcement is placed into it depending on what surface finish is required (the top surface is the side which is face down in the mould). A release agent can also be applied to the mould to assist with removing the part after curing.

Fibre is chopped in a hand-held gun and fed into a spray of catalyzed resin directed at the mould. The deposited materials are left to cure under standard atmospheric conditions. The polyester resins can be used with glass rovings is best suited for this process.

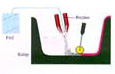

In this manufacturing method use two mold as male and female and is obtained two side smooth product. Special glass mat which was produced for the resin injection (continuous mat) is placed over molds and the molds overlap to each other. Polyester injects into the mold under pressure at a resin injection point. Resin injection method obtains better quality product than the handlayup and it is more quick and economic .

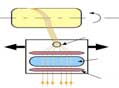

Hot press process is a compression molding involves molding a pre-manufactured compound in a closed mold under pressure and often using heat. A pre-manufactured compound is a combination of some or all of the following: thermoset resin, catalyst, mold release, pigment, filler, various additives, and fiber reinforcement.

Compounds can be produced in several forms, including flat sheet like sheet molding compound (SMC), dough like bulk molding compound (BMC), and wet molding compound. Hot press process gives high quality surface of the parts, a so-called "Class-A" surface.

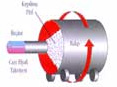

filament winding consists of winding continuous rovings of fiber onto a rotating mandrel in predetermined patterns. This method of manufacturing provides the greatest control over fiber placement and uniformity of structure.

Use to manufacture of products as pipes, tanks cylindrical pole. Glass fiber and polyester are sprayed into a rotating mold. Centrifugal force that consists from rotation of the mold allows to obtain both side smooth product.

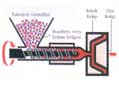

Pultrusion is a process used for making long, continuous components such as cable trays (for example, those used in the Channel Tunnel). Multiple strands of reinforcement fibres are pulled from reels along a conveyer-belt type process through guides into a heater. During this heating process the strands are coated in resin. The warm, resin-coated strands are then pulled through a moulding die, forming the final components shape. It is then cut to the desired length with a saw.

Continuous lamination is a continuous process for the production of flat or corrugated sheets or panels. The sheets are produced on a continuous moving belt process. Glass fiber reinforcement in the form of glass mats or cut glass rovings are spread on a moving belt, covered with a release film. A resin formulation is metered on top of the glass fiber. Then a second release film is put on top of the glass fiber. The whole package between the two films is then fed into an oven in which the curing takes place.

Extrusion machines are used in the molding of profile type products and injection machines are used in the molding of complex shaped products. In principle, injection and extrusion machines works in a similar way. Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing.

Compression moulding is normally used with pre-preg – reinforcement fibres already impregnated with resin. The pre-preg is placed in an open, heated female mould. The male mould is then placed down on to this with the combination of heat and pressure shaping and curing the component. Parts are then allowed to cool before removing from the mould.

Using long fiber thermoplastic (LFT) reinforcements in thermoplastic composite processes enables molders to produce structural or semi-structural parts, compounding the fiberglass in-line with injection or compression molding techniques.