- Telefon: 0 (232) 486 05 86

- info@kossecomposite.com

Epoxy is a chemical binder resin from thermoset group. Water, acid and alkali resistance is very good. It does not lose resistance features in time. Epoxy combination with glass or carbon fiber has excellent mechanical strength. Therefore, epoxy is used a lot of in the maritime sector and space and aviation technology.

Application methods

• Filament winding

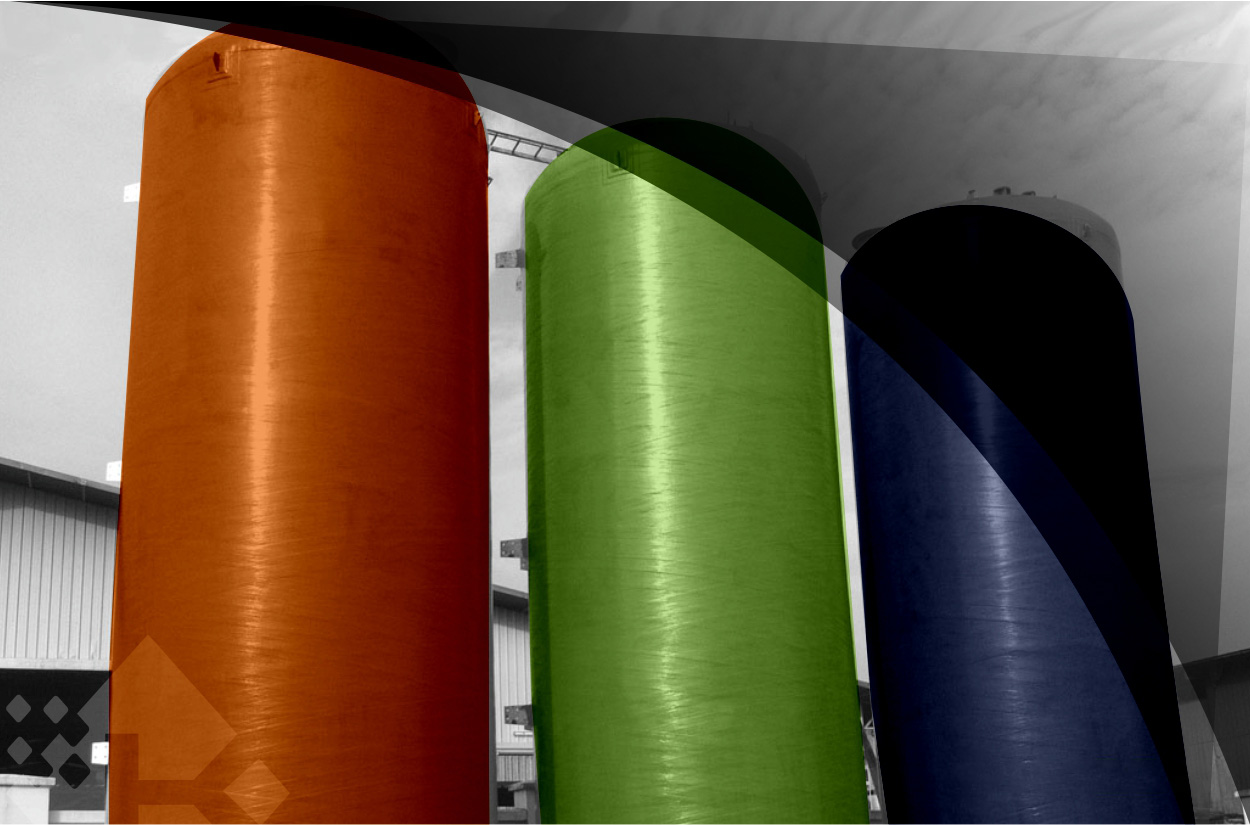

Vinylester resin, based on epoxy, has different chemical features from standart polyester resin. In this way, It has much higher heat resistance and chemical (acidic and basic environment) strength. Mechanical properties and deformation temperature under load (HDT) values are extremely high. This group resins are used to obtain GRP products by hand lay-up, injection, infusion, cold pressing, RTM, filament winding, pultrusion methods. Vinilester resins are used as the insulating material in the work place with chemicals, chemical tanks, storage and transport tank production, transfer pipes, marine vessels, automotive parts, wind turbine blades..

Vinyl ester resins are used as the insulating material of chemical storage and transport tanks production, pipelines, marine vehicles, automotive components, wind turbine blades, where worked with chemicals. In this area as well as aerospace and defense industry is a preferred resin type to achieve high performance composite products.

The structure of the vinyl ester has free hydroxyls terminals. Because of this structure, resins can be reinforced with glass, carbon and aramid fiber. As a result, very high mechanical values are obtainable.

Application methods

• Open Moulding: Hand-Lay / Fiber-spraying