- Telefon: 0 (232) 486 05 86

- info@kossecomposite.com

Kosse Composite is a firm that have gained experience in this sector and have expert engineering staff. In this direction offers services to you as follows.

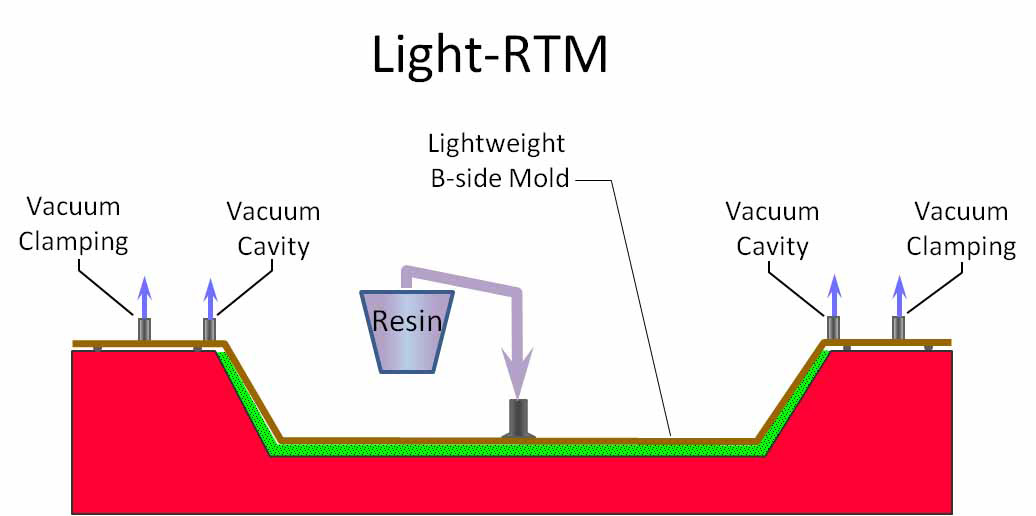

• Light-RTM process formingPlease contact us for more information

Kosse Composite with experiance 12 years in the composite industry and with expert engineering staff, is the solution partner for which firm wants to applicate L-RTM prosess and Kosse have the capacity to respond their needs. Moreover, our firm give serves L-RTM training courses to companies, individuals and / or organizations.

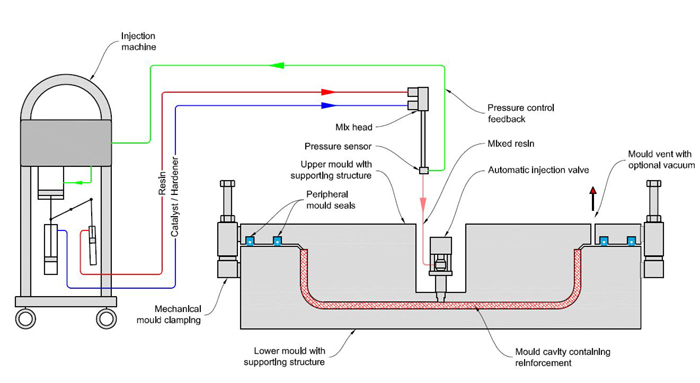

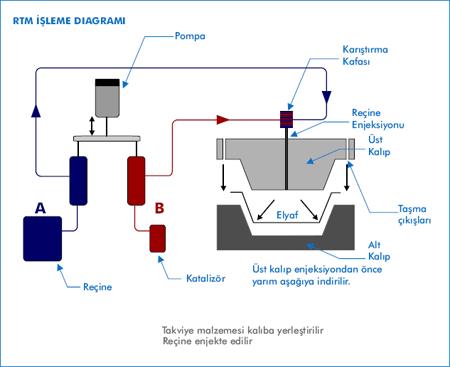

RTM method is used a frequently application for many sector as marine, automotive etc. at composite industry .

• Low styrene emission (near zero)

Use of resin infusion principle developed various production methods. These methods are standart RTM, light RTM, vacuum-assisted RTM VARTM and infusion.

Consumables of infusion

Resin infusionResin infusion is an advanced composite lamination tecnique. It provides to manufacture of unique quality and superior mechanical properties product. In recent years, a lot of developments have been recorded in designed for resin infusion polyester - vinyl ester resins, materials and equipment. Consequently, resin infusion method is an acceptable method as commercial. Many products can obtain.

Securlon®

Securlon® L-500 vacuum bag consists of multiply extruded polychloroprene. These layers decrease the formation of pinholes. It is not recommended for autoclave applications. Securlon L-500 works until 171 °C curing temperature.

Securlon®

Securlon® L-500 vacuum bag consists of multiply extruded polychloroprene. These layers decrease the formation of pinholes. It is not recommended for autoclave applications. Securlon L-500 works until 171 °C curing temperature.

Big Blue®

Big Blue vacuum bag is applicable to wide film applications and infusion. Big Blue works until 131°C curing temperature.

AT-200Y Sızdırmaz Bant®

AT-200Y is multifunctional, high-strength and economic adhesive bond. It can leave easily from metal or composite equipment. It can leave quickly from metal or composite equipment. AT-200Y works until 204°C curing temperature.

Econolease Peel Ply®

Very tightly woven nylon-based and silicone-coated peelply. It can easy separation and in addition surface appearance is fine-textured. It is designed for use in hand lay-up and resin infusion.

Econoply E®

Econoply E is a two-tier peel ply is use and if too much polyester and difficult separation. It has been developed for infusion applications. It eliminates the need for sanding. Econoply E Works until 149°C curing temperature.

Bleeder Lease® B

It retains the heat with protective layer and it facilitates to the resin flow. Bleeder Lease® B Works until 121 °C curing degrees

Greenflow 75

Green flow 75 use to spread equally to the resin with minimum wastage. It is designed to work with polyester, vinylester and epoxy.

Greenflow 185®

It is designed for help of resin flow during the vacuum-assisted infusion. It is a thickset and mid-level resin spread mesh. Greenflow 185 works until 125 ° curing degrees.

Polyetylene spiral winding

it is use for as vacuum manifold.

Airhold 10 CBS Bant®

Double-faced reinforced adhesive tape. During the polyethylene resin infusion is using to fasten spiral winding. Other uses during the process, atached to honeycomb core material and is subsequently removal without trace.

RIC®

Resin infusion connector is designed for vacuum manifold and resin application on low temperature and to improve the efficiency of resin feeding connections. RIC works until 80 °C curing degrees.

Of313 Omega Resin Flow Line®

It uses under bag in the single or double bag resin infusion applications instead of polyetylene spiral winding. It transfers of the resin from in itself into the product throughout surface with omega form. Omega lines are translucent silicon and reusable.

Polietilen T-Fiting 3/8"

T connection is use for the resin and vacuum lines.

Polietilen L-Fiting 3/8"

It is the elbow joint and uses for the resin and vacuum lines.

Airweave ® N10

Airweave ® N10 uses that need high pressure applications. It clutch the surface gorgeously.

Airseal 1

Airseal 1 is a tigh vacuum baggıng band and designed for low cost commercial applications and economical applications. It is a tigh band with the AT-200Y feature. Airseal 1 B Works until 150 °C curing degrees.

Reçine Hattı Klempi

Resin line clamp is made of professional quality grippin pliers for use in resin infusion. It prevent resin flow that stops feed lines connections in vacuum. It is fully adjustable, nickel-plated, anti-slip and has ergonomic design.

Vactrak

The most important features of vactrak, its one side is adhesive with fiber and the other side is same Airhold 10 CBC feature. With this feature, it provides to bonding between fiber layers and a very high vacuum permeability.

Resintrak

It provides to bonding features between layers due to fiber structure and helps for resin flow.

Tac-Strip Bant

Tac-Strip cam elyaftan üretilmiş ağ formunda banttır. Her iki tarafında yüksek yapıştırma gücüne sahip basınca duyarlı yapışkan bulunmaktadır.